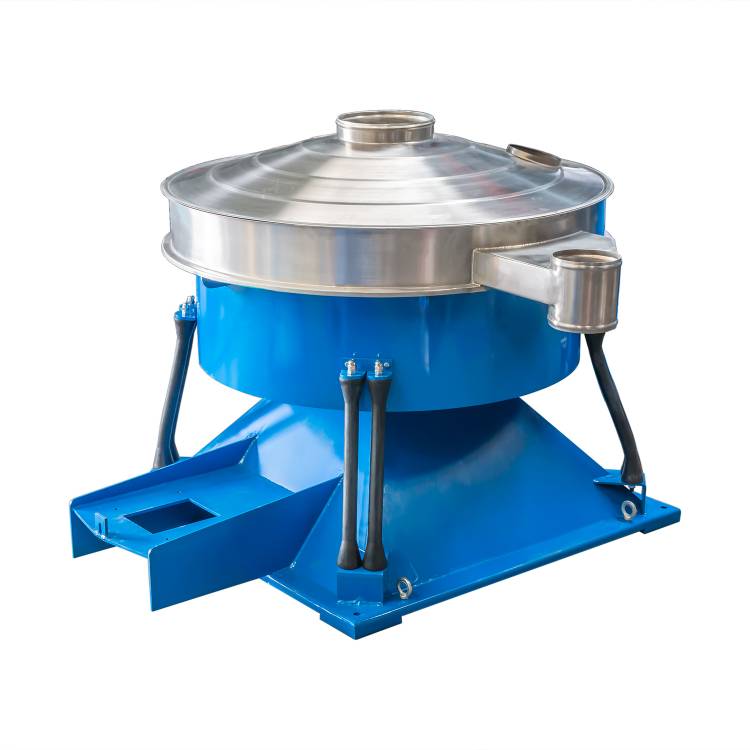

Tumbler screening machine

Tumbler screening machine is a high output and fine powder material screening equipment.

Description

Product brief

Tumbler screening machine is a high output and fine powder material screening equipment. It’s motion trajectory is similar to manual screening. Tumbler screen uses elliptical action which aids in screening of even very fine material.

Working principle

Tumbler screening generates three-dimensional tumbling motion. Three- dimensional elliptical movement helps in perfect grading. The radical inclination makes the material move from center to outwards & tangential inclination makes it move in circular pattern; thus, an accurate gradation is finished with ease.

Features:

Pneumatic lifting device make the easy clean and change screen mesh.

Manufactured up to 5 Decks and 6 different sized products.

Use ordinary motor without vibration, long service life.

Automatic cleaning system to improve the screening efficiency

Parameters

| Model | BY1800 |

| Diameter | 1800mm |

| Area(M2) | 2.46 |

| Mesh size | 0.028mm-12mm |

| Power | 4KW |

| Layer | 1-3 layer |

| Material | SS: Stainless steel – MS: mild steel |

| Feeding material size | 0-20mm |

| Product sort size variety | 2-5 different sized product |

| Screen motion | Three dimensional: Eccentric, Radial and Tangent |

| Net Cleaning | Bouncing ball,Ultrasonic device,Rolling brush |

| Leakage proof design | 100% full enclose dust proof |

Application:

Tumbler screening is used for screening the following material such as Quartz Filler, Silica Flour,Mica Powder & Mica Scrap, Potash Feldspar & Sodium Feldspar,Dolomite Powder, Limestone & Quick or Hydrated Lime Calcite Powder,Bentonite Powder,Talc Powder , Soap Stone Powder etc.

Deblinding System for tumbler screener

The Deblinding System include bouncing ball, roller brush and ultrasonic.

Send Inquiry

You Might Also Like