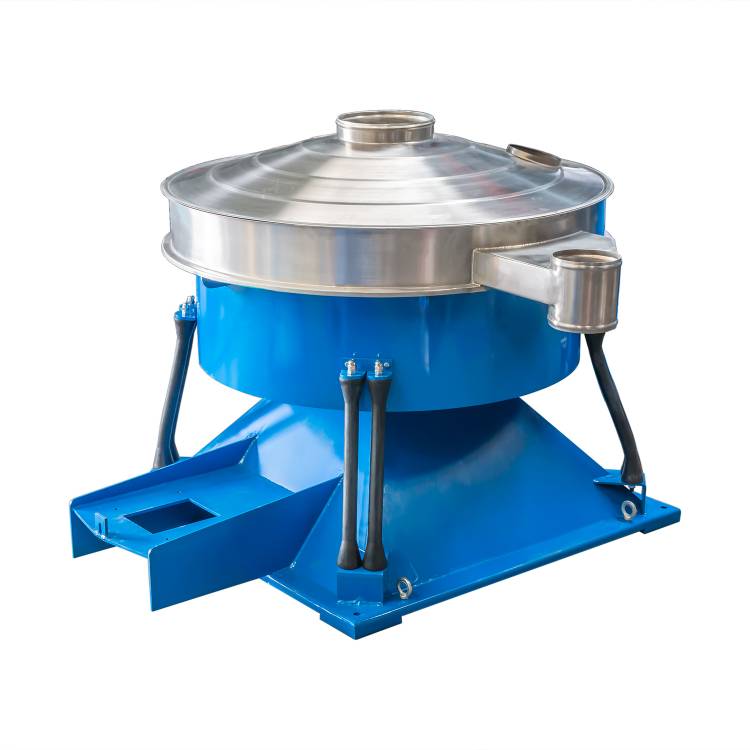

Tumbler screener

Tumbler screener is large yields and ultra fine screening equipment with motion trajectory is similar to manual screening.

Description

Product brief

Tumbler screener is large yields and ultra fine screening equipment with motion trajectory is similar to manual screening. It’s output can be up to 5-10 times of rotary screen for superfine powder material.

Working principle

The tumbler screener generate a three dimension elliptical movement which is composed of radial & tangential inclination. This motion modular make the material uniformly distribute on the whole screen surface from center towards periphery, every product residence time on screen surface can be adjusted.

Features:

Pneumatic lifting device make the easy clean and change screen mesh.

Impurity and coarse material automatically discharge

Low noise less than 75db

Can be continuously work 7/24-365 days

Long service life because of no vibration

Low energy consumption

Parameters

| Model | RY2600 |

| Diameter | 2600mm |

| Area(M2) | 5.31 |

| Mesh size | 0.028mm-12mm |

| Power | 5.5KW |

| Layer | 1-5 layer |

| Material | SS: Stainless steel – MS: mild steel |

| Feeding material size | 0-20mm |

| Product sort size variety | 2-5 different sized product |

| Screen motion | Three dimensional: Eccentric, Radial and Tangent |

| Net Cleaning | Bouncing ball,Ultrasonic device,Rolling brush |

| Leakage proof design | 100% full enclose dust proof |

Application:

It is widely used in chemistry, pharmaceutical, food processing, mining, plastics, stone and soil, metallurgy, recycling industries in order to sort small, heavy, light, dry, dusty, wet and sticky materials which are less than a millimeter.

Deblinding System for tumbler screener

The Deblinding System include bouncing ball, roller brush and ultrasonic.

Send Inquiry

You Might Also Like